MILITARY GRADE ARMOR STEEL 46100/12560

MIL–DTL 46100/12560 - BALLISTICS TESTED

Mil–DTL 46100/12560 steel plate are military spec armor steel. They are typically used in military vehicles. They exhibit high-hardness/strength that is approved for use within the Department of the Army and is available for use by all Departments and Agencies of the Department of Defense. Hankev carries a broad stock of approved material.

About Us

MIL–DTL 46100

MIL–DTL 46100 (REV E) steel plate is military spec armor steel. It exhibits high-hardness that is approved for use within the Department of the Army and is available for use by all Departments and Agencies of the Department of Defense. Hankev carries a broad stock of approved material.

Applications vary, but typically armor 41600 steel plate is used to stop high-velocity projectiles (HVPs). This High-Hardness Armor (HHA) steel plate is especially useful to protect structures or vehicles from sniper fire or any form of weapon that will emit the HVPs. Depending on the threat level, various thicknesses of steel may be required to manufacture the product. The threat level is determined by three factors – the size of the round that the product is meant to defend, the speed at which that round is traveling, and the distance the round will travel before reaching the target.

The steel is quenched and tempered at very high temperatures to sustain a tough surface for the best levels of protection. The surface hardness of this material is between 477 and 534 BHN. While the material can be formed, it is important to note that due to its ductile limitations, it should not be bent improperly.

Our stock is always available in the latest revision - the newly revised MIL-DTL-46100 Rev E. We also stock Rev D Amd 1 heat treated plate to support the needs of previous vehicle platforms requiring this material.

MIL–DTL 12560

MIL–DTL 12560 (REV J) steel plate is a military spec armor steel plate that is approved by the Material Technology Laboratory, Department of the Army, for use in combat vehicles and for ammunition testing. Thickness ranges from 3/16” through 3” are for use in combat vehicles and ¼” through 12” are for use in proof acceptance testing of armor defeating ammunition.

Typically this grade of armor is used in the protection of landmines or explosive structures. It absorbs shock very well and therefore helps to keep shrapnel to a minimum. Each plate is tested to a Fragment Simulated Projectile standard, which dictates the level of protection for which the plate will ultimately be used.

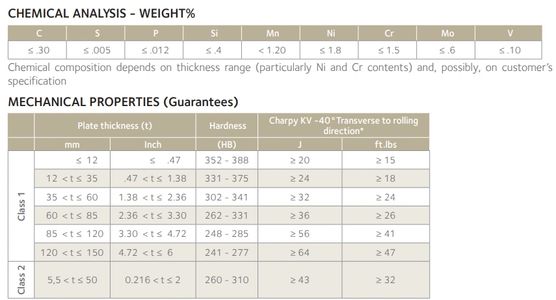

Largely known as Rolled Homogenous Armor (RHA), this variety comes in four different classes. Typical BHN readings on this material are 377 to 415 with other impact and bend tests being performed as well.

Our stock is always in the latest revision -- the newly revised MIL-DTL-12560 Rev J. We also stock Rev H to support the needs of previous vehicle platforms requiring this material.

This grade of heat treated plate includes 4 Classes

Class 1 - For resistance to penetration

Class 2 - For resistance to shock

Class 3 - For evaluation only. This Class of heat treated plate is not used on vehicles

Class 4 - For maximum resistance to penetration

Military grade steel plate

3/16’’-1’’ (Gauge) x 48’’-96’’ (Width) x 96-288’’ (Length)

What's the differences between MIL-DTL-12560 armor vs MIL-DTL-46100?

ANSWER:

MIL-DTL-12560 is extremely good at absorbing shock compared to MIL-DTL-46100.

MIL-DTL-46100 is typically used to stop hyper-velocity projectiles, and not so much to protect from landmines and explosives.